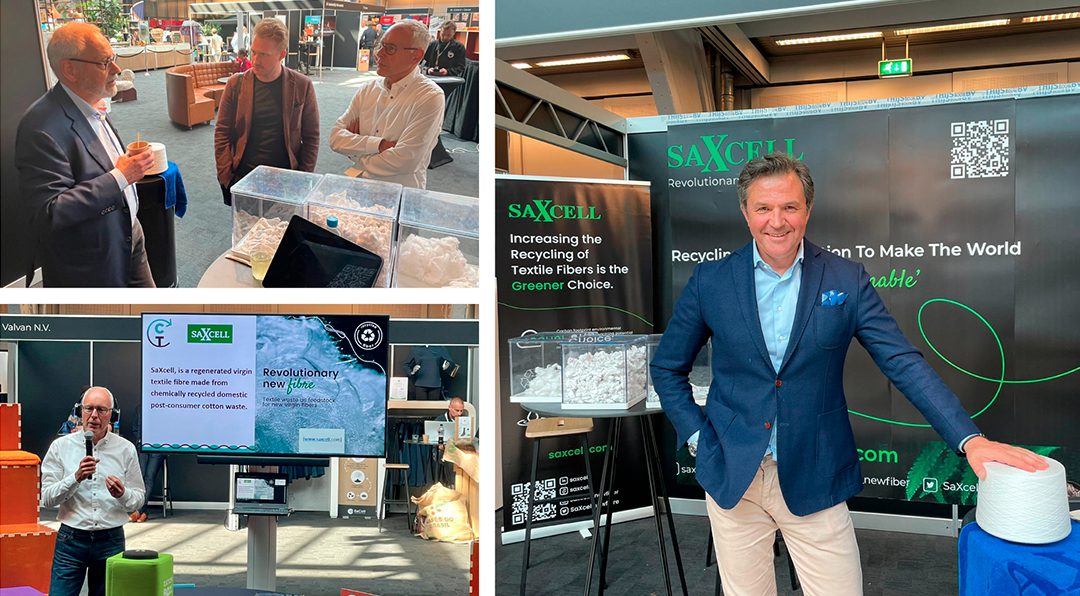

Global Fibre Congress celebrated in Dornbirn

We were at the 62nd Global Fibre Congress celebrated in Dornbirn, Austria. Leading companies in the textile sector talked about circularity, recycling, and sustainability as the pathway to paving the future by reducing the impact of the textile industry on the environment.

Read more...